An outstanding commitment to excellence is what makes Quality Synthetic Rubber (QSR) a partner you can trust. Through a systematic process of continuous improvement and performance optimization, QSR maintains a steadfast focus on providing customers with products that exceed expectations.

QSR operates the following:

QSR is a member of ASQ, the global knowledge network that links the best ideas, tools, and quality experts.

- AS9100 and ISO/TS 16949 certified quality management programs

- Environmental management system meeting ISO 14001 requirements

- Product development methodology executed in accordance with AIAG APQP guidelines

- Streamlined project management system providing full visibility and tracking of ongoing operations

- Well-established LEAN Manufacturing program

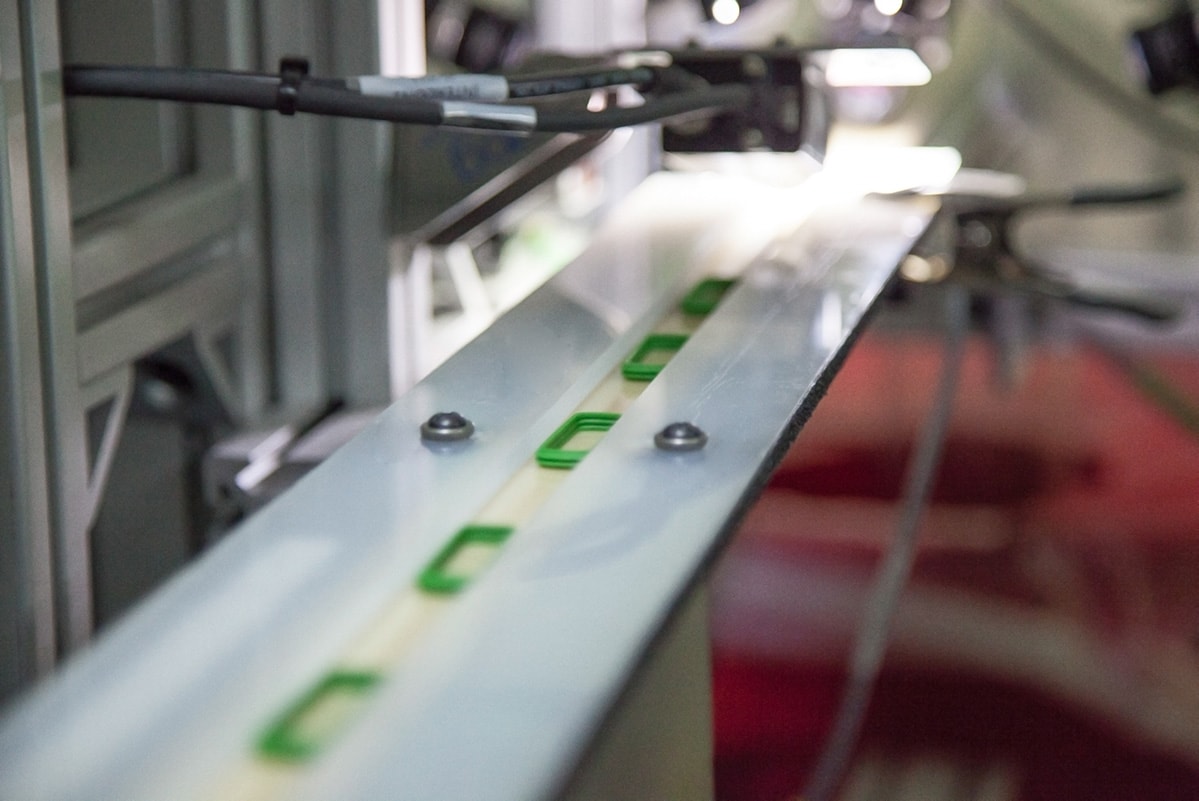

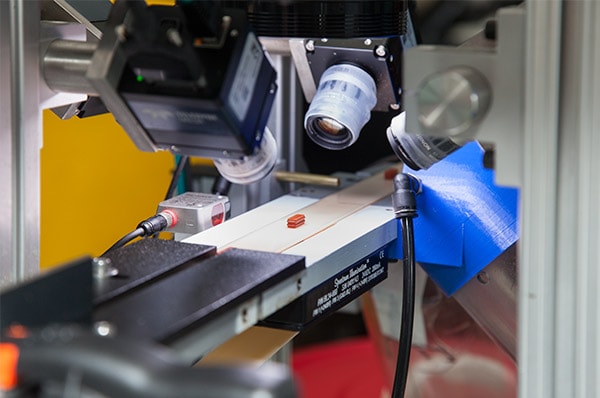

- Layered Process Audit System (LPA) to monitor manufacturing processes to ensure effectiveness

- A sophisticated lot traceability system to control and record every step of the process